Laser Cutting Machines

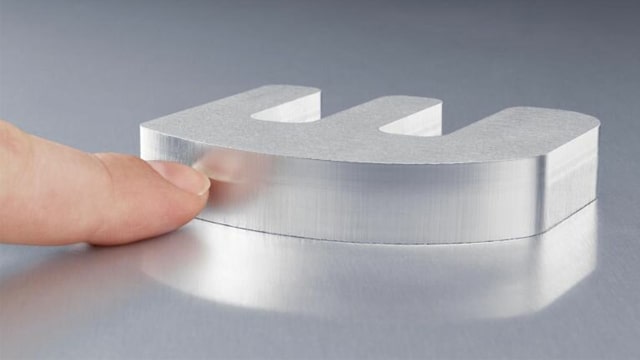

The laser cutting machines TruLaser 5030 / 5040 / 5060 represent high productivity, efficiency, and high-quality results. They are characterized by speed and reliable processes. Diverse automation solutions and intelligent functions guarantee excellent results in continuous operation – the smooth edges produced by the CO2 laser also offer clear-cut benefits. The perfect machine for excellent laser cutting.