Retriever

CNC Plasma Burning & Steel Plate Cutting

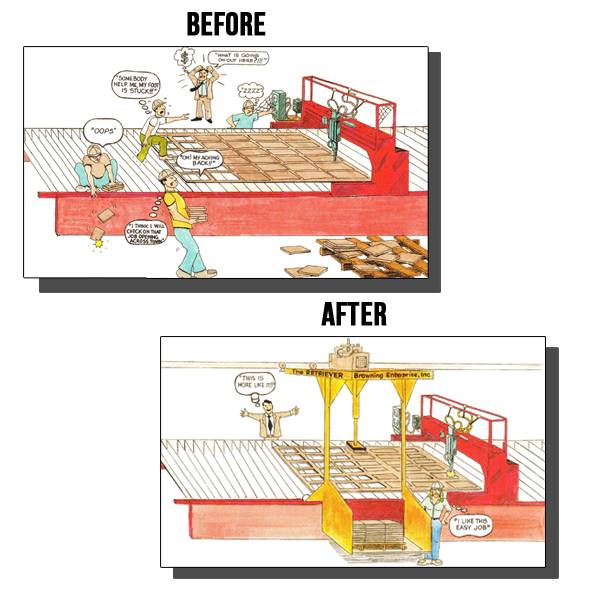

In July of 1995 Browning Enterprise, Inc., purchased a plasma burning system for our steel processing division located in Northeast Alabama. This was the culmination of nine months of investigation into the burning system technology at many facilities. Early in this investigation it became apparent that although the technology to increase the speed of burning had advanced tremendously, there was the growing challenge of removing the finished material from the table. The most common approach to the material handling problem is with hand magnets and man power. This has several negative points:

- Violation of safety standards

- Strenuous (possible back injury)

- Dangerous (possible foot injury in slats)

- Slow (loss of production)

- Bottom line – Costly

Through trial and error, and mostly out of necessity, we have developed the Retriever. The addition of this system to our burning machine has greatly enhanced productivity, improved safety and ease of operation of the whole system. So much so, that several factory representatives and machine tool salesmen who have seen this system urged us to offer this system to the industry.

Are you using a slow, costly and dangerous method?

If so you need ‘The Retriever’ because:

- It offers all these features at the price of a 4,000# forklift.

- It is safe and meets OSHA standards.

- It helps prevent back, leg and feet injuries.

- It increases productivity up to 30%.

- It reduces absenteeism because it improves job satisfaction.

The Retriever is solidly built, easy to install and very reliable. Features include:

- High load capacity wheels-handles machine weight (approximately 10,000#) plus 4,000# in pay load.

- Adjustable palletizing area on carriage is standard.

- Operator grinding and marking station integral to the unloading process which allows one man to handle a complete burn to finished part operation.

This station allows finger tip access to:

- Grinder

- Grinding rocks and wrench

- Control of operation

- Markers

- Drawing to identify parts #

- Flatness checking

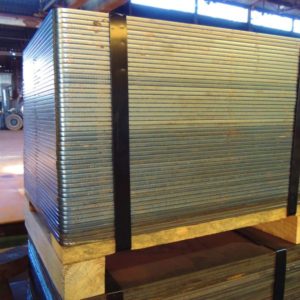

- Metal parts are retrieved from the burn table via the carriage. The carriage arm can be mounted with the standard magnetic grip rated at 5,000# lifting capability, or as an option, a vacuum cup may be used for aluminum or stainless steel alloys.

- Grinding table is designed to easily flip the parts where most of the grinding is required. The table can be modified as needed for a wide variety of different part nesting and holding requirements.

- Carriage window will accommodate 84 inch parts. As an option it can be modified if larger parts are more frequently run.

- Standard machine comes complete.

Customer is responsible for

- Connecting electricity 240/480 AC 3 Phase to machine control box.

- Installing angle rail on floor (operator side)

- Installing beam for trolley on rear of machine

The easy to install Retriever carries a full six-month warranty. FOB Attalla, Alabama Allow 8 weeks for delivery.